Reverse Engineering

Metal Spray is used in a process called reverse engineering. Reverse engineering is used when no spare parts are available after a component fails or is damaged. Reverse engineering involves working in reverse on the design of an object to achieve the original design information. An example of this could be a classic car part that has corroded or worn over time. In this instance, no spare parts would be available as the parts are no longer made. Using this method enables fast creation of parts which in turn minimises production downtime.

The Steps of Reverse Engineering

- Inspection of the damaged part.

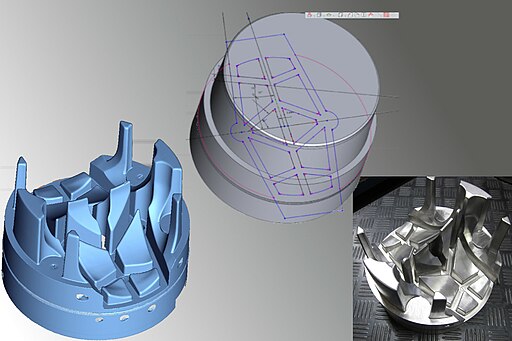

- 3D scanning of part to achieve original design information.

- Once 3D scanning has produced a CAD model, depending on the size of the component, a 3D printed model may be created prior to manufacturing to ensure a correct fit.

- Component preparation and excess material removal.

- Material replacement using Metal/Thermal Spray.

- Re-machining.

Using one of the Metal Spray processes to repair a damaged part is often a more cost-effective option than purchasing a new part (if they are available) as it shortens the development cycle. Identifying the cause of the damage/corrosion assists in in the identification of a more suitable coating. Metal Spraying will in turn increase the lifespan of the salvaged part to more than what a new part could achieve.