SprayWatch systems provide accurate data to enable the best understanding of thermal spray processes. With that knowledge, the user can optimize the process for the best coating quality as well as to minimize production costs, waste and environmental stress.

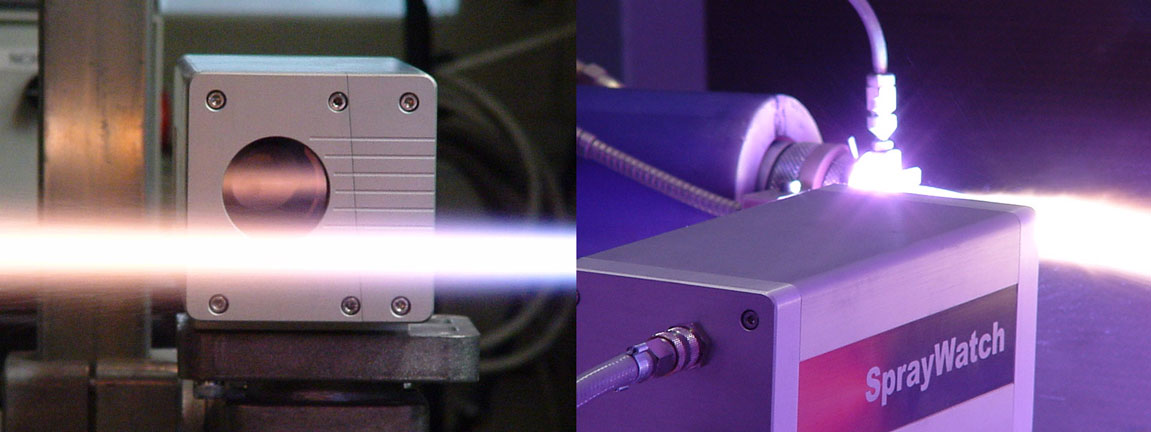

Oseir’s SprayWatch product family is the solution for quality assurance and diagnostics needs of the thermal spray industry. It combines the measurement of the most important thermal spray parameters into a single, inexpensive and robust system that is easy to adapt and use. SprayWatch systems measure particle velocity, size (SprayWatch 2S only) and trajectory, as well as temperature (SprayWatch G does not measure temperature), density, position and heading of the particle plume. SprayWatch systems are very portable and easy to use. Since 1999, Oseir has delivered several hundred systems with excellent reliability record to satisfied users around the world - to be used not only in research and development, but also in daily quality control of the thermal spray processes.

SprayWatch Range

For more detailed information on the SprayWatch product range, Click Here to go to the Oseir website.

SprayWatch 2S

SprayWatch 2S system is the top-of-the-line system giving maximum amount of information of thermal spray processes. It can be used in most thermal spray processes including Plasma, HVOF, HVAF, Arc and Flame spraying.

- All camera settings can be controlled from the computer keyboard outside the spray booth for added convenience. This is especially important when frequently measuring widely varying processes.

- SprayWatch 2S has the widest range of focus distance setting enabling matching of the measured area with the spray plume width in most cases to catch maximum amount of particle data.

- SprayWatch 2S is the only system that measures also particle size in Plasma, Arc and Flame spraying.

- SprayWatch 2S uses a high-speed USB camera, which can be easily connected to any suitable computer or laptop with one free USB 2.0 or better.

SprayWatch 4S

SprayWatch 4S is the most sensitive SprayWatch system especially for HVOF and HVAF processes, however, it works well also on the other processes.

- It measures everything except particle size.

- With SprayWatch 4S, camera focus, distance and lens aperture are adjusted mechanically on the camera inside the booth. But if only a few processes are measured in a booth, these settings can be probably set once and there is no need to change between the processes.

- SprayWatch 4S is very portable. The camera weighs approx. 1 kg / 2 lbs.

- It is very compact and only needs a USB extension cord and +12 VDC power supply (both of which are provided with the system).

- SprayWatch 4S uses a high-speed USB camera, which can be easily connected to any suitable computer or laptop with one free USB port (2.0 or better).

- As an option, the SprayWatch 4S camera can be also delivered with a 45 degree mirror end piece to allow for installation on the robot aligned with the thermal spray gun for continuous monitoring of the process when the spray time is longer or there is some other reason requiring continuous monitoring.

SprayWatch G

SprayWatch G is the little brother of the other units. It is intended to be used mainly for optimization of deposition efficiency on daily basis with Plasma spraying, but can also be used to monitor Arc and Flame spraying.

- It measures the particle velocity, plume density and plume position, heading compared to the Plasma flame position.

Each time that a Plasma system is started, the flame may be in a slightly different position. If this shift is not compensated for (by adjusting the carrier gas), the deposition efficiency is reduced. In conjunction, the coating thickness control may also not be optimal. By adjusting the carrier gas to make sure most particles reach the “sweet spot” of the plasma flame, the user can maximize the DE and coating thickness control.

The camera is small and easy to mount in a fixed position in the booth (where the plasma gun can be brought to check the process and optimize the settings every time before actually spraying the part) to ensure best results.

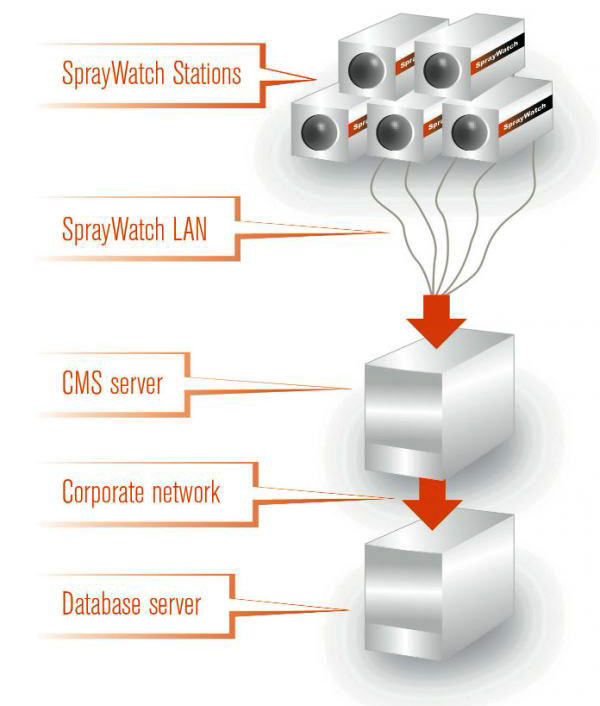

SprayWatch CMS

SprayWatch CMS (short for central monitoring system) is for larger installations with multiple booths equipped with any combination of SprayWatch thermal spray diagnostic systems.

- It collects the measured quality data from all of the systems into a single central database computer with backups and other features.

- It also allows control of the various SprayWatch systems connected to the central computer to ensure reliable and easy use.

For more information including technical information, contact us on (07) 3823 1004 or send your enquiry via our contact form.