Applications

A tungsten grit application can prolong the life of a component by 3 to 5 times (depending on the application) which can make a substantial difference to running costs.

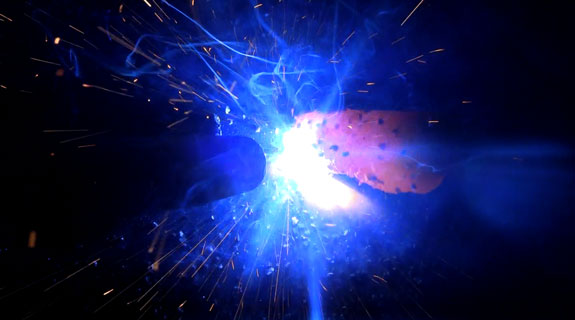

Ground-engaging tools and equipment used in construction, excavation and earth-moving, is commonly associated with the tungsten hard-facing process. Ground engaging blades/teeth and ripper points on dozers and cat trucks are just some of the numerous applications that this process is used on.

When painted components are subject to hard-facing, the application area is often grit-blasted initially in order to provide a better surface for the tungsten to bind to.

Ground Engaging Blades Grit-Blasted (Left), with Tungsten Application (Right)

Other Applications Include

- Augers.

- Bed shapers.

- Chisel plow points.

- Ditch and trencher teeth.

- Down the hole drilling equipment (DTH).

- Dozer buckets.

- Drill bits.

- Excavator tools.

- Grader and scraper blades.

- Mining picks.

- Mower skids.

- Plough shears.

- Scarifier points.

- Shredder hammers.

- Slurry agitators.

- Slurry paddles.

- Toolbar shanks.

We also supply the hard-facing wire and tungsten grit to suit your application.

For more information on our MSSA Tungsten Feeder or consumables, call us on 07 3823 1004, or email us using our contact form.