AK HVAF systems work reliably with LPG fuels such as propane, propane-butane, propylene and MAPP-gas as well as with methane and natural gas.

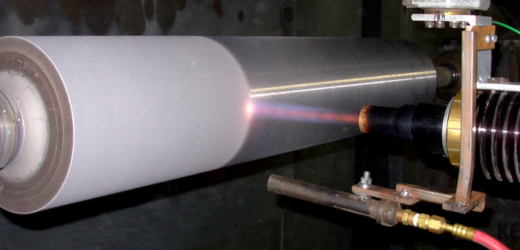

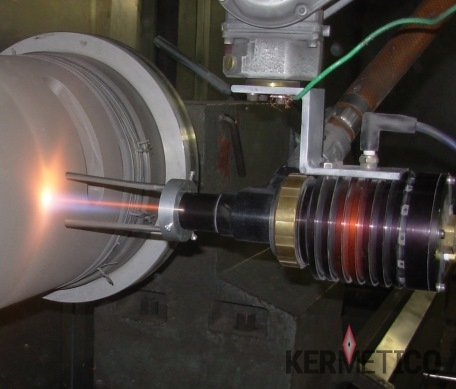

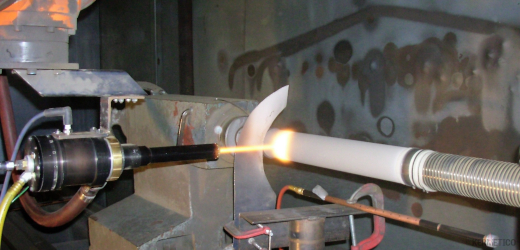

The HVAF systems spray metals and carbides at optimal temperature without overheating, and are used for spraying bulk-like gas and liquid impermeable wear and corrosion-resistant coatings.

We supply a large variety of different guns in our AK HVAF product line, with a wide tuning range that allows for metal spraying, MCrAlY, chromium carbide, tungsten carbide and other stainless steel, nickel and cobalt-based coatings.

For more information on the particular HVAF AK Guns, click on the relevant tabs below.

- AK5 – a gun to spray smaller parts, thin walls, and complex surfaces.

Sprays cermet compositions (1-15 to 5-30 microns), metals and alloys (10-30 and 10-45 microns). - AK5-ID – a compact gun to spray internal surfaces 200 mm (8″) and larger.

Sprays tungsten carbide onto internal diameters. - AK6 – a tungsten carbide gun to spray a balanced mix of parts.

Sprays tungsten carbide, chromium carbide (1-20 to 15-30 microns). - AK7 – a high-power gun for thermal spray of large parts.

Sprays tungsten carbide, chromium carbide, pure metals and alloys (from stainless steels to MCrAlY). - AK-ID – an 80 mm (3.15”) and larger internal diameter spray gun.

Sprays tungsten carbide and Hastelloy-type coatings. - AK-IDR – a rotating ID gun to spray bores 100 mm (4”) and larger.

Sprays carbides onto internal diameters. - AK-HH – a manual gun for on-site work.

Sprays tungsten carbide and chromium carbide (3-15 to 5-30 microns), metals and alloys (10-30 to 20-53 microns).

AK thermal spray equipment consists of one or more spray guns, a control console with an operator tablet, a powder feeder, a vaporizer and a set of cables and hoses. Each AK system can run several guns. Custom control systems to run multiple guns simultaneously are available upon request.

Each AK machine is on-site friendly, wheel-mounted and does not need a water chiller.

For particular information regarding coating of internal diameters, Click Here.

For hand held manual model HVAF AK-HH, Click Here.

As the Australian Distributor for Kermetico HVAF/HVOF Metal Spray Equipment, MSSA supply the full range of Kermetico systems, spray guns and spare parts.

Advantages

HVAF 50% Higher Efficiency (over HVOF) - Significant Cost Savings

- HVAF spray just a fraction of the HVOF spray time, with higher deposition efficiency, with coatings harder and longer lasting

- 20-30% higher deposition efficiency, 30% less hardness deviation than any HVOF system

- By choosing Kermetico AK HVAF, a HVOF job shop gains at least a 50% cost advantage to HVOF competitors and additional coating quality advantage as a “bonus.”

- No oxygen in HVAF mode – just compressed air, which costs 10 times less.

- Easy-to-change specialized guns allow spraying each part in the most efficient way.

- The same setup is used for blasting and thermal spray coating using the same gun that results in further reductions of time.

- The cost of consumed spare parts is 1/10 of the conventional HVOF expenses for the same work.

- The Kermetico HVAF AK line is an all-in-one system operating several specific guns: Universal, big OD, small OD, ID, rotating ID and hand-held. This requires less investment in a Kermetico HVAF system and makes the payback period shorter.

The Use of Propane, Propane-Butane, Propylene, MAPP-Gas, Methane and Natural Gas for High Velocity Thermal Spray Coatings

Propane, C3H8, one of the liquefied petroleum gases (LPG) group, a by-product of natural gas processing and petroleum refining. Specific heat capacity – 1.67 KJ/ (Kg*K).

Propylene, C3H6, also known as propene or methyl ethylene, has a slightly lower boiling point than propane and is thus more volatile. Specific heat capacity – 1.5 KJ/ (Kg*K).

Propane-Butane is a mix of propane and butane. In some countries, it is much less expensive and easier to find than pure propane.

“MAPP gas” is a trademarked name, belonging to The Linde Group for a fuel gas based on a stabilized mixture of methylacetylene (propyne) and propadiene. The name comes from the original chemical composition, methylacetylene-propadiene propane. “MAPP gas” is also widely used as a generic name for UN 1060 stabilized methylacetylene-propadiene (unstabilized methylacetylene-propadiene is known as MAPD). In the spring of 2008, the only remaining plant in North America discontinued true MAPP gas production. Current products labeled “MAPP” are, in fact, MAPP substitutes. These versions are stabilized liquefied petroleum gas (LPG) with high levels of propylene.

Methane, CH4, is the main component of natural gas. Specific heat capacity – 2,22 KJ/ (Kg*K).

Natural gas is a naturally occurring hydrocarbon gas mixture consisting primarily of methane, but commonly including varying amounts of other higher alkanes, Specific heat capacity – 2,34 KJ/ (Kg*K).

It is possible to pre-set the AK equipment to work with any of these gases, some of them, like propane-butane or natural gas, will need additional hardware to prepare it properly.

Advantages of Kermetico HVAF AK Spray Machines Compared to Other Systems

Kermetico's AK High Velocity Air Fuel Process

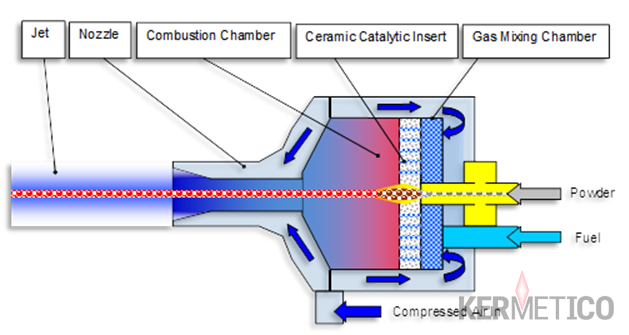

The quality and efficiency of Kermetico AK equipment is the result of the relatively low combustion temperature of an air-fuel mixture combined with the axial injection of the feedstock through the long combustion chamber, where the low gas velocity provides sufficient time for the powder particles gradual heating. The materials’ acceleration occurs in the nozzle that has a large diameter. The large diameter of the nozzle is needed to pass through the volume of nitrogen present in the combustion air. It also ensures that the nozzle walls do not interact with the particles, allowing the use of a nozzle that is as long as needed for feedstock acceleration, typically from 800 to over 1,000 m/s (2,625-3,280 ft./sec.). The Ceramic Catalytic Insert is used in the combustion chamber to provide a broad range of stable combustion parameters.

The Kermetico AK HVAF system deposits coatings with 5-6 times higher spray rates, 20-30% higher deposition efficiency, 30% less deviation than any HVOF system. When choosing a Kermetico AK system, a job shop gains at least a 50% cost advantage over HVOF competitors and gains an additional coating quality advantage as a “bonus.”

Key Features of HVAF and HVOF Tungsten Carbide Coatings

The Kermetico HVAF process produces WC-based coatings with the highest fracture toughness, substantially exceeding known HVOF coatings. Since the main mechanism of wear of WC-base coatings is attributed to the material brittleness, Kermetico’s HVAF coating exhibits better wear resistance.

| WCCoCr 86/10/4 Coating Feature | Typical HVOF | Kermetico HVAF Mode | ||

| Economy | Balanced | Ultra | ||

| Deposit Efficiency (%) | 40-55 | 60-70 | 48-58 | 36-42 |

| Hardness (HV300) | 1,050-1,250 | 1,050-1,250 | 1,250-1,350 | 1,350-1,600+ |

| Apparent Metallographic Porosity | <0.8 | <0.8 | <0.5 | <0.3 |

| Bond Strength, PSI (MPa) | 12,000+ (80+) | |||

| Range of as-sprayed Roughness, µm (µ in.) | 3.5-4.5 (150-180) | 1-3.2 (40-130) | ||

Hydrogen Injection, Combustion Chamber Pressure Measurements and Safety Interlocks

The Option for Hydrogen Injection Provides Better Particle Temperature Control and Prevents Materials Oxidation

The AK guns may be used with hydrogen injection. The control of hydrogen injection provides an additional tool for the particle temperature regulation due to the high thermal conductivity of hydrogen as well as the additional protection of the spray material from oxidation. The average flow of hydrogen in an AK gun is under 20 SLPM, and it has a negligible effect on the combustion process and particle velocity.

Combustion Chamber Pressure Measurements and Safety Interlocks

The AK guns provide the means for the measurement of combustion chamber pressure, which is an essential technological parameter of the HVAF spray process.

We use the data from the combustion chamber pressure transducer for the detection of the powder carrier gas flow during the gun ignition process. This allows creating a safety interlock for preventing gun ignition if no flow of carrier gas was detected preventing the possibility of a flash-back into the powder hose and flow of combustible gases into the powder feeder.

HVAF High-Pressure Blast Feeder

(10 Times Faster, 100 Times Less Grit Used)

The standalone HVAF High-Pressure Hot Blasting Grit Feeder is designed to feed Kermetico HVAF guns with grit media. The HVAF High-Pressure Hot Blasting Grit Feeder prepares high-quality clean metal surfaces minimizing the time and grit blasting media consumed.

- Surface preparation by HVAF grit blasting increases the production rate 10-fold with a 100-fold reduction of grit consumption compared to conventional grit blasting with compressed air.

- The same setup is used for blasting and thermal spray coating using the same gun that results in further reductions of time for the thermal spray coating job.

- HVAF blasting is also an efficient tool for hard coating stripping.

For more information on this equipment or consumables, call us on 07 3823 1004, or email us using our contact form.