Advantages of Kermetico HVAF AK Spray Machines Compared to Other Systems

Kermetico's AK High Velocity Air Fuel Process

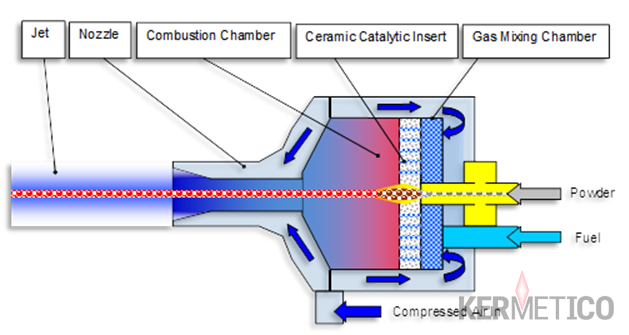

The quality and efficiency of Kermetico AK equipment is the result of the relatively low combustion temperature of an air-fuel mixture combined with the axial injection of the feedstock through the long combustion chamber, where the low gas velocity provides sufficient time for the powder particles gradual heating. The materials’ acceleration occurs in the nozzle that has a large diameter. The large diameter of the nozzle is needed to pass through the volume of nitrogen present in the combustion air. It also ensures that the nozzle walls do not interact with the particles, allowing the use of a nozzle that is as long as needed for feedstock acceleration, typically from 800 to over 1,000 m/s (2,625-3,280 ft./sec.). The Ceramic Catalytic Insert is used in the combustion chamber to provide a broad range of stable combustion parameters.

The Kermetico AK HVAF system deposits coatings with 5-6 times higher spray rates, 20-30% higher deposition efficiency, 30% less deviation than any HVOF system. When choosing a Kermetico AK system, a job shop gains at least a 50% cost advantage over HVOF competitors and gains an additional coating quality advantage as a “bonus.”