Wear Protection of Turbine Rotors with HVAF and HVOF

Kermetico HVAF technology and equipment allows the deposition of impermeable, hard and ductile coatings to protect turbine rotors from corrosion and wear.

The high ductility of our rotor coating reduces the risk of cracking if flexed and provides loading stress resistance, while the gas-tight structure provides corrosion resistance.

The HVAF Coating of a Geothermal Rotor after Solvent Cleaning

The Wear and Corrosion Factors of Turbomachinery Rotors

Pitting Corrosion of Steam Turbine Rotors

Pitting, corrosion fatigue and stress corrosion cracking problems all occur in steam turbines. The primary corrodents are sodium hydroxide, chloride, sulfates and sulfides.

Usually, the level of contaminants present in steam is not high enough to corrode the system components. As steam expands through a turbine, the solubility of contaminants in the steam decreases. They condense onto surfaces at solution concentrations much higher than the original contaminant level in the steam. These concentrated solutions promote system corrosion.

Rotor pitting corrosion is commonly associated with chloride deposits.

Flow-Accelerated Corrosion of Steam Turbine Rotors

Flow-accelerated corrosion of carbon and low-alloy steels in the steam path two-phase flow has been less widespread in fossil plants than in nuclear plants; however, it has occurred in some locations, like rotor seal areas and rotor shaft-last disk transitions.

Geothermal Turbines Corrosion

The geothermal corrosive environment determines the choice of highly corrosion-resistant materials for rotors and blades. Different rotor and blade materials frequently result in electrochemical corrosion.

Due to the galvanic corrosion effect, rotor materials were subjected to more severe crevice corrosion than blade materials. The stress corrosion cracking initiation and propagation did not occur after 4,000 hours of corrosion testing in H2S free waters, although the sulfide induced stress corrosion cracking took place in water with hydrogen sulfide.

Those are the reasons why different techniques of surface treatment are being used to protect turbine rotor surfaces.

The Features of Kermetico HVAF Coating Technology

Kermetico High Velocity Air Fuel (HVAF) technology has been shown to be very competitive in the protection of turbine rotors from corrosion and wear.

Thicker layer HVAF rotor coatings provide an option to refurbish even heavily worn rotors.

The high velocity of the Kermetico HVAF in-flight particles (over 1,000 m/s) enables the production of very dense coatings with high adhesion.

Moreover, the low combustion spraying temperature (1,960-2,010°C | 3,560-3,650°F) and gentle particle heating lead to minimal feedstock phase transformation and almost nonexistent elemental depletion/decomposition of the in-flight particles.

Furthermore, the replacement of pure oxygen necessary for HVOF with air in our HVAF process significantly reduces the oxide content of our coatings, which is desirable for high-performance coatings.

The Kermetico HVAF Rotor Coating Method

The traditional thermal spray approach is to melt and atomize the feedstock, propel it to the surface of the target part whereupon contact ‘splat cooling’ builds up a coating.

The Kermetico HVAF process operates on a different principle “heat slowly, spray faster.“

We heat the feedstock material to near its liquid phase temperature without exceeding it.

Then we accelerate the particles to an optimized high velocity, and when the particles impact the substrate, there is a rapid conversion of kinetic to thermal energy that allows for plastic deformation of the particle and a bond that we cannot accurately measure.

In the ASTM 633C bond test, the only result we get is broken glue at 12 KSI, even with 0.040“ (1 mm) of WCCo 88/12.

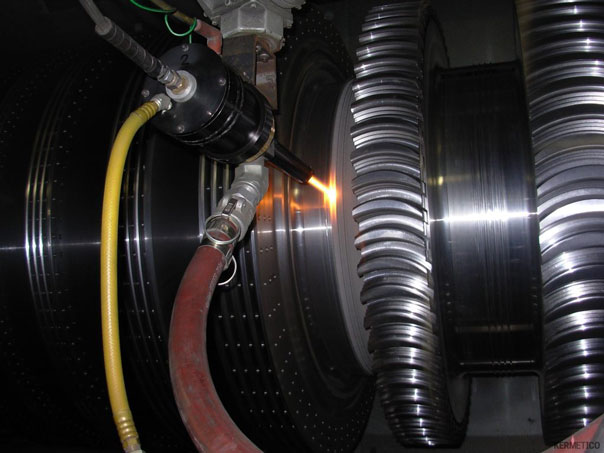

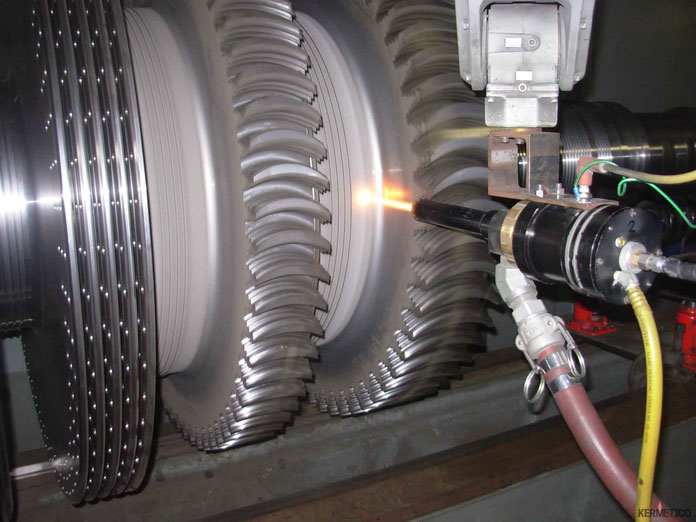

Kermetico HVAF AK7 System Depositing a Coating onto Labyrinth Seals of a Geothermal Turbine Rotor